Rheology of Complex Fluids

Rheology of biological gels ♦ Rheology of MR fluids ♦ Fragmentation of complex fluids and gels ♦ Characterizing thixotropic elasto-visco-plastic materials ♦ Rheo-electric characterization of carbon black gels

Interfaces, Wetting and Drag Reduction

Drag reduction using streamwise riblet surfaces

Rheology of Complex Fluids

Rheology of biological gels

Caroline Wagner studies biological gels, mucus in particular, with the aim of predicting their macroscopic rheological response from considerations of their microstructure. This allows us to elucidate the aggregation mechanisms of these networks, with an ultimate goal of understanding the origin of the mechanical changes observed in diseased mucus. The studies are performed through a combined approach of polymer modeling and rheological experimentation in conjunction with the Ribbeck laboratory in Biological Engineering.

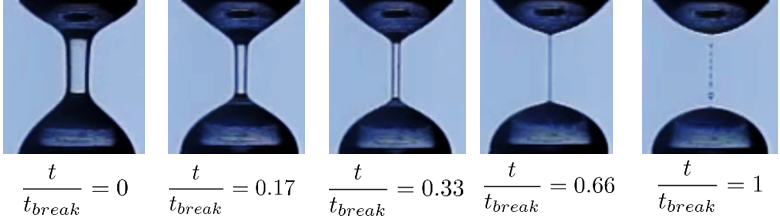

Capillary breakup extensional rheometry of saliva.

Capillary breakup of (left) fresh saliva sample and (right) the same sample after 11 hours.

Rheology of magneto-rheological (MR) fluids

Yonatan Tekleab studies magnetorheological (MR) fluids - liquid suspensions of magnetic particles. MR fluids have the unique property of rapidly changing their rheological properties under the influence of an applied magnetic field. Unlike some complex fluids, the fluid property changes are immediately reversible. MR fluids can be found in a variety of applications ranging from lubrication to damping systems.

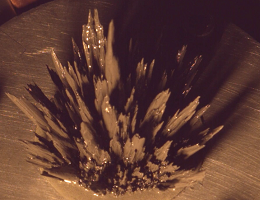

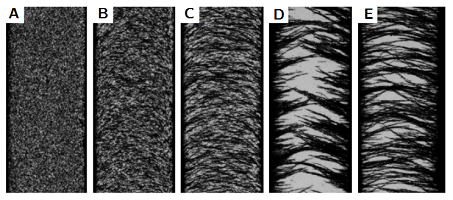

(Left) MR fluid on a plate with an applied magnetic field; the peaks align with the magnetic field lines.

(Right) Evolution of aggregate microstructure of MR fluid. The applied field is off in A, and increases in strength from B to E.

Fragmentation and fracture of complex liquids and gels

|

Many industrial and biological applications involve fracture or fragmentation of soft matter. Atomization of paint, disintegration of bio-fluids in coughing/sneezing, break up of ink drops or jets in 3D printers, spray of anti-misting fuel agents in airplane engines, and fracture of soft gels used in food industry are few examples in which a micro-structured liquid or gel goes through fast, non-linear deformations. One interesting example is a class of protein gels known as Casein gels, which are widely used in many food products. Bavand Keshavarz, along with Thibaut Divoux and Sébastien Manneville, study the linear rheology of these gels at different concentrations. They have performed in-situ rheology and modeled its behavior using a simple fractional model. These gels are similar to a critical gel even many hours after gelation. Electronic and confocal microscopy of the network combined with precise rheological measurements are used to help find connections between the fractional models and the physical properties of the underlying network. Find out more about this research here. (Image on left) Cracks formed in a Casein gel inside a custom-built transparent Couette cell on a Discovery HR-3 rheometer. |

Characterization and modeling of thixotropic elasto-visco-plastic (EVP) materials

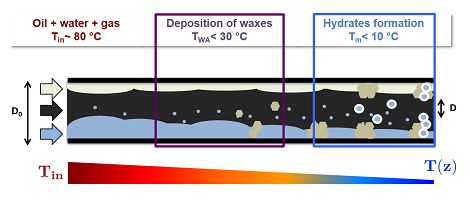

Thixotropic Elasto-Visco-Plastic (TEVP) materials are substances that display a combination of viscoelastic behavior at small deformations, while flowing plastically at large deformations above a threshold yield stress. The majority of substances that we use directly or indirectly on a daily basis, including foodstuff, consumer products, pharmaceuticals, coatings, inks, paints, biofluids and biomaterials fall into this broad category of TEVP materials. Michela Geri studies the behavior of two specific types of TEVP materials - waxy crude oils and clathrate hydrates - in collaboration with Chevron ETC. In deepwater fields, as the oil is extracted from the well and cooled down by the surrounding water, paraffin waxes and hydrates start to appear as solid particles, changing the mechanical response of the oil and posing a serious risk to the operability of the pipelines. Her goal is to characterize the rheological behavior of crude oils when waxes or hydrates are present, and to model this response with appropriate and consistent constitutive equations.

Read more about this research here.

Wax and hydrate particles begin to appear as crude oil cools down inside pipelines through which it is pumped.

Rheo-electric characterization of carbon black gels

|

Ionically and electronically conductive complex fluids represent an important class of materials with applications in flow battery technologies. In particular, electrolyte suspensions containing carbon black nano-conductor networks show promise for novel semi-solid flow cell designs. As the conductive semi-solid suspension is pumped, the attractive colloidal network in the suspension is prone to rupture leading to a decrease of conductivity and, consequently, cell performance. Characterizing the rheology, wall slip and conductivity of the semi-solid suspension under flow is therefore crucial for cell modeling and design. Ahmed Helal aims to characterize the rheo-electric properties of the carbon black gels by performing in-situ simultaneous rheo-electric measurements on stress-controlled torsional rheometers, using a custom-made test fixture.

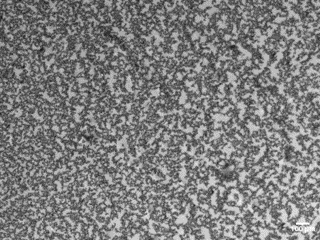

(Left) Micrograph of conductive carbon nanoparticles in ER fluid. |

Interfaces, Wetting and Drag Reduction

Drag reduction using streamwise riblet surfaces

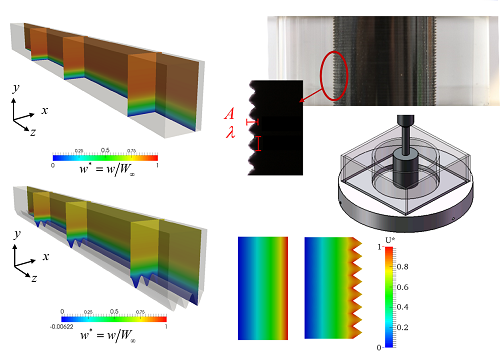

Drag reduction using streamwise riblets is inspired by the ridges on shark denticles, and has been shown to be an effective method of passive drag reduction. Streamwise riblets modify the boundary layer of the flow, in both laminar and turbulent regimes, to reduce the shear stress at the wall. In turbulent flow they have been shown to be effective in pushing vortical structures away from the wall and thus reducing the drag force on the walls. Shabnam Raayai-Ardakani studies the effect of different geometric parameters on the amount of drag reduction using numerical as well as experimental methods (boundary layer and Taylor-Couette flows), and is trying to understand how best to tune the geometry of the wall to provide optimum drag reduction.

Carefully designed streamwise riblets can give drag reduction in boundary layer (left) as well as Taylor-Couette flow (right).